Okay, folks, gather ’round. I’m gonna share a little something from my recent to-do list that turned into a bit more of an adventure than I bargained for. We’re talking about anthony door parts. Yeah, sounds thrilling, I know.

My Little Project: The Stubborn Cooler Door

So, I’ve got this old commercial cooler in the garage. Picked it up cheap a while back, mostly for drinks and overflow during holidays. Thing’s built like a tank, an Anthony, I later found out. Anyway, the door started gettin’ real saggy on one side, and the seal, well, it wasn’t exactly sealing anymore. You could feel the cold air just pourin’ out. Not good for the electricity bill, let me tell ya.

First things first, I had to figure out what was actually wrong. Took a good hard look, wiggled the door, poked at the gasket. Seemed like the bottom hinge was shot, and that old gasket was definitely brittle and cracked. “Alright,” I thought, “should be simple enough. Just get new parts.” Ha! Famous last words.

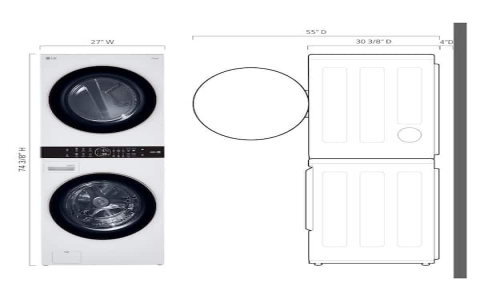

Identifying the exact Anthony door parts I needed was the first hurdle. It’s not like popping down to the local hardware store for a doorknob. These commercial things, they’ve got models, series numbers, and sometimes those labels are long gone or covered in years of grime. I spent a good afternoon squinting at faded tags and then trawling the internet. You type in “Anthony door hinge” and a million things pop up. Which one is my hinge? That was the question.

I eventually found a diagram that looked kinda like my setup. Took some measurements of the old hinge, compared the hole patterns. For the gasket, it was a bit easier – measure the door, look at the profile of the old gasket. Still, you’re kinda hoping you’re ordering the right stuff, ’cause returns can be a pain.

Getting Down to Brass Tacks

Once the parts arrived – and thankfully, they looked right – it was time to get my hands dirty. This is where the “practice” really began. I thought the gasket would be the easy part. Wrong again! Getting the old, hardened gasket out of its channel was a proper wrestling match. It tore, it stuck, I think I sweated more doing that than my morning workout. Used a scraper, some pliers, a lot of patience.

Then, installing the new one. You gotta work it into the channel just right. Start at a corner, press it in, move along. Took a couple of tries to get it seated all the way around without any bunching. My fingers were sore, man.

Next up, the hinge. This was the bit I was more worried about, ’cause the door is heavy. I propped the door up on some wood blocks to take the weight. Getting the old, worn-out hinge off wasn’t too bad, just a few bolts. But then, lining up the new hinge with the holes on the door and the frame, while keeping everything aligned… that took some finessing. Had to loosen things, wiggle the door, tighten a bit, check the level, loosen again. It was a slow dance.

- Propped the door securely – safety first, right?

- Removed the old, busted hinge.

- Cleaned up the area – good to get rid of old gunk.

- Carefully aligned the new hinge. This was tricky.

- Bolted it in, bit by bit, checking alignment constantly.

Finally, after a fair bit of adjusting and tightening, the new hinge was on. I slowly removed the blocks, and the door… it swung beautifully! And it sealed! Oh, the satisfaction of that solid ‘thunk’ when it closed, and no more cold air escaping. It was like a new cooler.

So, yeah, that was my journey into the world of Anthony door parts. It wasn’t rocket science, but it definitely took more time and patience than I initially figured. You learn a lot by just doing it yourself, though. Saved some cash, got the job done, and now I know a heck of a lot more about commercial cooler doors than I ever thought I would. And the beer is staying properly cold, which is the main thing, right?